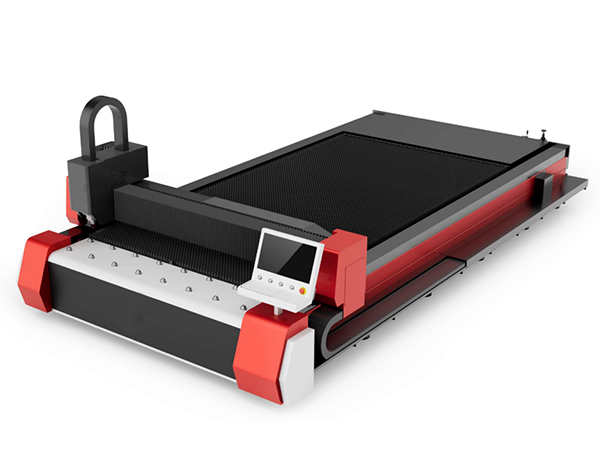

- Fiber Laser Cutting Machine KDF-3015

- No.:KDF-3015

- Category:Fiber Laser Cutting Machine

- Evaluation:( 0 ) record

- Hits:1002

It is widely applied in industrial pipeline processing, explosion-proof equipment, military industry, chemical industry, oil exploration, lamps and lanterns, metal processing, ironware, building, etc.

1, Power consumption is only 20-30% of co2 laser cutting machine.

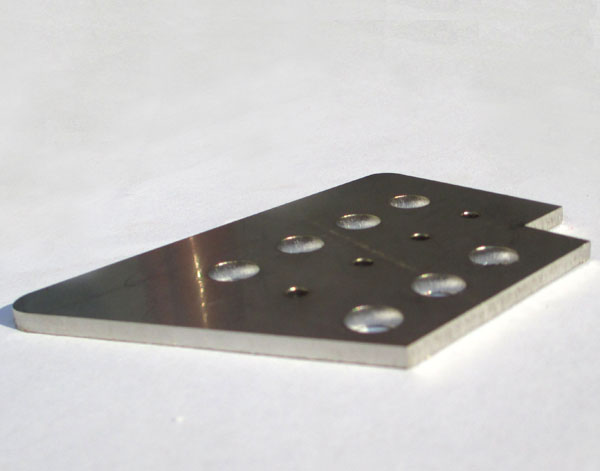

2, Be able to easily cut simple or complex parts

3, Adopts imported famous brand fiber laser generator /Life time reach 100,000hrs

4, With imported servo motor and gearing system ensure the accurate cutting

5, High quality cut without other extra polishing.

6, Higher cutting speed and efficiency, speed of cutting plate over 10 meters per minute

7, Non-contact working way, won’t deform your products.

8, Be able to cut complex designs.

Stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet and other metal pipes and tubes.

|

Model |

KDF-3015 |

|

Laser type |

Fiber Laser |

|

Laser wavelength |

1070nm |

|

Laser output power |

1000W-6000W |

|

Cutting area(mm)(L×W) |

3000mm×1500mm |

|

Maximum speed(m/min) |

120 m/min |

|

Min line width |

< 0.15mm |

|

Maximum acceleration |

1.2G |

|

Positioning accuracy |

± 0.03 mm |

|

Minimum cutting width |

0.15mm |

|

Driving Way |

Imported servo motor |

|

Transiting Way |

Dual-drive & rack and pinion system |

|

Operational Temp Range |

10 ~ 40ºC |

|

Electrical Requirements |

380V/50Hz |

|

Cooling Style |

Water cooled |

|

Continuous working time |

24 hours |

|

Cutting speed and thickness |

Depends on the material |

|

Weight |

About 4800kg |

|

Outline size(mm) |

4700mm×2300mm×2000mm (L×W×H) |