- Mould Laser Welding Machine

- No.:KWJ-200M

- Category:YAG Laser Welding Machine

- Evaluation:( 0 ) record

- Hits:566

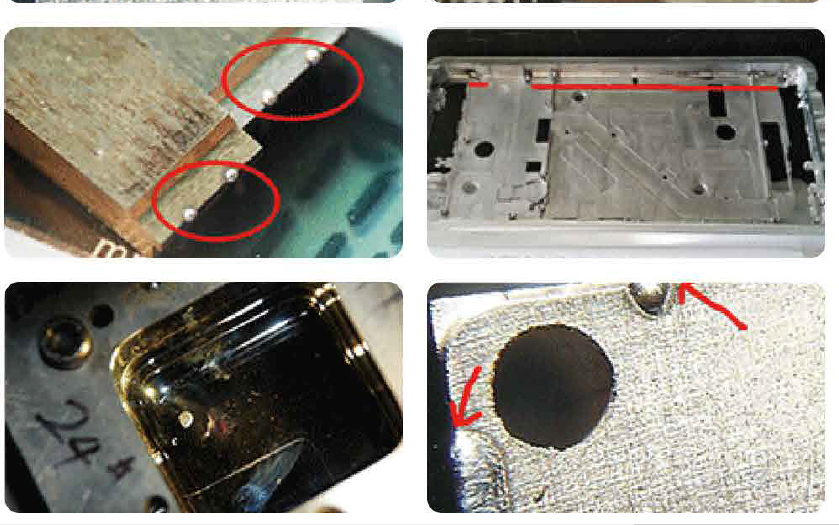

Introduction: Mould laser welding machine is mainly used in large-scale moulds' repairing, precisely repair sand holes,cracks,broken and worn parts on mould. It is controlled by Industrial micro-computer. Through the high energy of heat that’s instantly generated by laser to melt the welding wire and connect it with the damaged parts, it can firmly connect with the original material, after grinding to reface the mould.

Repair and welding different kinds of moulds, precise instruments, and other metal parts .

1, Equipped with self-developed welding system.

2, Simple operation, beautiful weld seam,high welding speed and no consumables.

3, The heat affected area is small,and will not cause the mould deformation .

4, Deep welding, it’s firm and beautiful.

5, Compact design,save the occupied space and is easy to move.

6, Flexible welding arm,it’s adjustable forwardly or backwardly, turnable to left or right. Applicable to different types mould.

7, With industrial water chiller,constant temperature controlling system,protect the whole welding machine .

8, High reliability and can be continuously and stably processed 24 hours work.

Repair and welding different kinds of moulds, precise instruments, and other metal parts .

|

Model No. |

KWJ-200M |

|

Wavelength |

1064nm |

|

Pulse width |

0.1-10ms |

|

Frequency |

1-20Hz |

|

Max. output power |

200W/ 400W |

|

Spot size |

0.2-2mm |

|

Control type |

Touch screen |

|

Cooling type |

Water Cooling, separately |

|

Input power |

AC220V ± 5% , 50/60Hz |

|

Power consumption |

≤6KW |

|

Wavelength |

1064nm |

|

Pulse width |

0.1-10ms |

|

Observing System |

CCD Camera and Microscope |

|

Packing dimension |

140×70×135 cm 70×68×57 cm |

|

Weight |

N.W: 250kg G.W: 300kg |